When You Wanted Gold But Got Gravel

If it seems too good to be true…

We were recently asked by a client to do some work a custom ring that they had made by another jeweler. This is a fairly common occurrence for us since we have a full, in-house jewelry repair facility. The problems started when it was time to polish the ring.

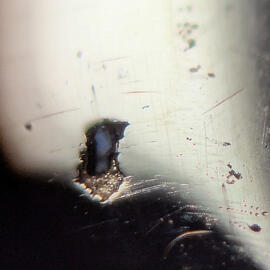

To the naked eye, the ring looked decent enough except that the surface was not as smooth and bright as it should be. But, no matter how carefully our jewelers polished, the piece simply refused to take on a normal, bright finish. So, we decided to take a closer look using our gemology microscope. We were not prepared for what we saw.

To fully understand the problems with this ring, you have to know a bit about how jewelry is made. The modern process that is used for a ring like this (lost wax casting) is fairly straightforward:

- Carve or 3D print the design in wax.

- Place the wax in a metal chamber and then fill that with a plaster-like material called investment.

- Once the investment hardens, burn out the wax in an oven.

- Fill the space left by the wax with molten gold using either a vacuum or a centrifuge.

Casting can be a tricky thing. If the temperature of the investment and the gold is not perfect, or if the force that is applied to the gold is too little (or too much), or if the channel for the gold to follow isn’t properly setup, you can wind up with a brittle casting due to what is called “porosity.” The metal looks ok from the outside, but underneath the surface it is more like a sponge than a solid piece.

As you might have guessed, this particular ring was riddled with porosity. To make matters worse, there were tiny bits of silica embedded in the metal. How did they get there? Well, before the modern casting process described above was invented, jewelers used a simpler version called “sand casting.” In sand casting, the process is similar except that instead of using investment, the piece is pushed into a moldable, sand-like material to create an impression. Then, instead of using a vacuum or centrifuge to force the gold in, it is typically poured using gravity alone.

Now, don’t get the wrong impression, sand casting is a seriously cool technique that can be used to create a lot of beautiful and high quality pieces. But, it’s not the ideal process for a ring like this exactly because of the issues that we saw. It also requires a lot of specialized skill to get right. If it’s not done correctly, porosity is going to happen. It is also common for tiny bits of the sand material to wind up in the finished product.

So, there you have it. On the surface, this ring looked like a great deal. Unfortunately, that good price came at a high cost. This story is a good reminder of how important it is to work with a trustworthy jeweler. If you are looking for a jeweler that will be upfront, honest, and deliver high-quality jewelry every time, we hope you’ll give us a try. Reach out anytime.